.jpg)

CARBIDE END MILL CUTTER

Frequently Asked Questions:

Questions: How many flutes of end mill cutter?

Answer: 2 flutes end mill, 3 flutes end mill, 4 flutes end mill are common flutes we produced.

6 flutes end mill is also available.

Questions: What kind of end mill cutter do you manufacture?

Answer: Square end mill (also called flat end mill)

Ball nose end mill (also called ball end mill)

Corner radius end mill (also called bull nose end mill)

End mill cutter for aluminum.

Questions: What is the brand of end mill cutter?

Answer: The brand of end mill cutter is Echain.

Questions: What is the guarantee for end mills?

Answer: All end mills are 100% inspected by professional inspectors with precision quality inspection equipment.

Questions: How hardness of workpieces end mill cutter can be used on?

Answer: The import carbide rod of end mill cutter can process on hardness up to 55HRC.

Questions: What’s the tolerance of end mill cutter?

Answer: International tolerance standard h5, tolerance range control at μlevel accuracy.

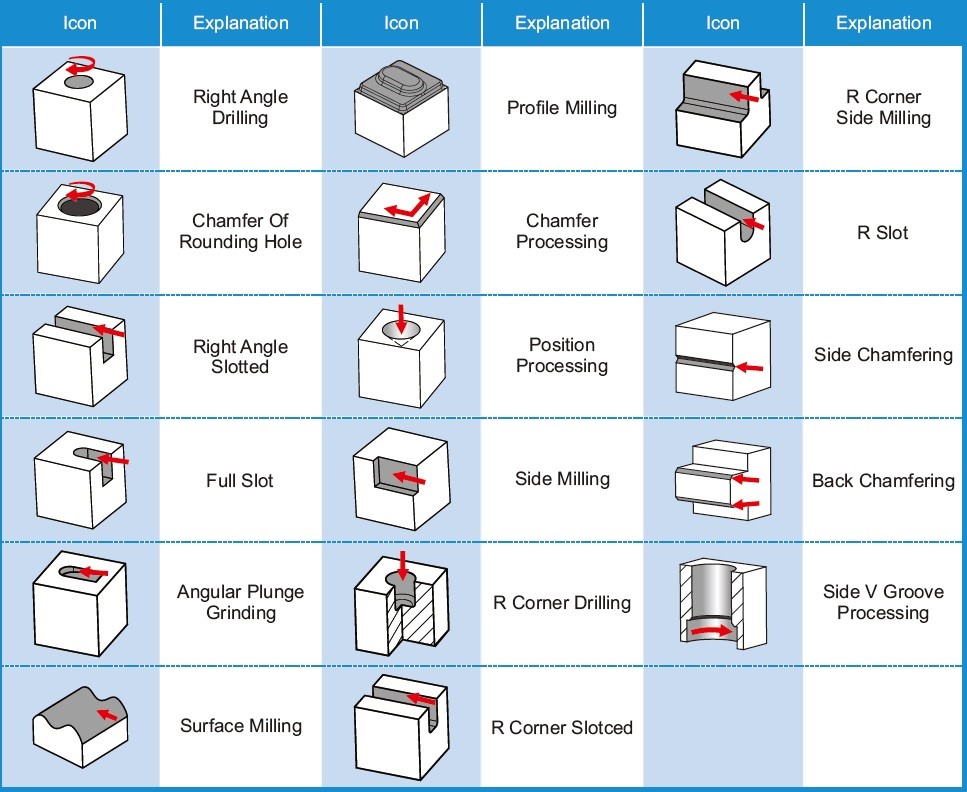

Questions: What common processing can end mills be used in?

Answer: Ball end mill can be used on profile milling, surface milling, and R slotting.

Square end mill can be used on angular plunge milling, full slotting, and right angle slotting.

Bull end mill can be used on profile milling, surface milling, R corner Side milling, R slotting, and R slotting.

Features of MU2-GMA (For Aluminum)

- New design double edges round flute can high speed operation with long life.

- Mirror grinding for aluminum operation with double edge helix design for a sharp and excellent smooth surface.

- Use a high-quality carbide rod.

- For 55 HRC general-purpose applications.

- Control tolerance by international standard h5 with micrometer level.

- Different series can be chosen.

All 5 Axis grinding machines are from Walter in Germany.

Top quality carbide rod.

Features of MU-GMM (For steel)

- New design round flute can high speed operation with long life.

- New EC nano-coating perfect match with high hardness carbide rod with ideal chip flow geometry.

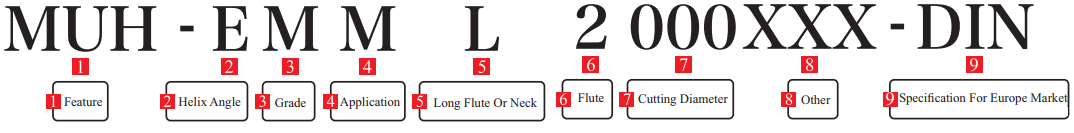

Carbide End Mill Identification System

① Feature

⑧ Other

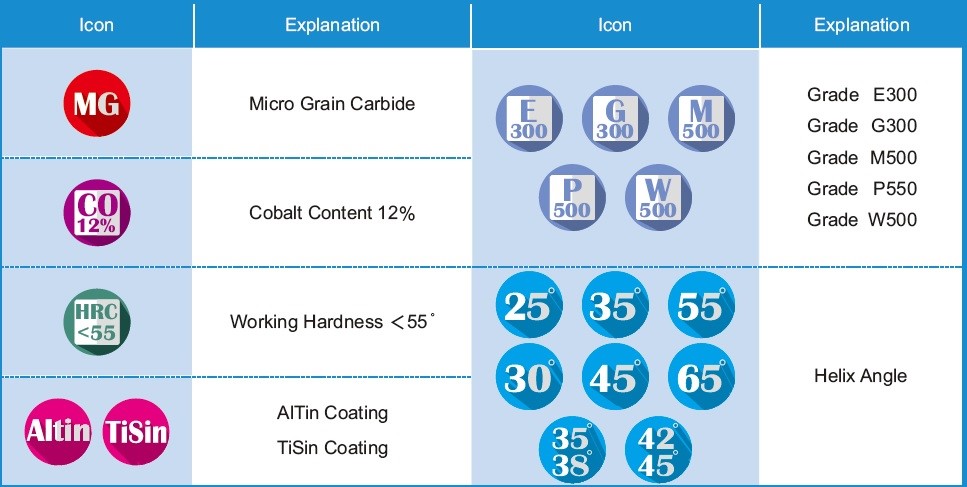

Specification Icon Guide

Processing Icon Guide

Keywords of processing icon chart:

Right Angle, Drilling, Side, Chamfering, Angular Plunge Grinding, Side Milling, Chamfer Of Rounding Hole, Back Chamfering, Full Slot, Incline Side Milling, Side V Groove Processing, Internal R Corner Side Milling, Surface Milling, Chamfer Slotced, R Slot, Position Processing, Backside R Chamfering, Chamfer, R Corner Drilling, Backside Inner R Chamfering, Outer R Chamfer, Internal R Slotced, R Corner Slotced, Round Hole Outside R Chamfering, R Corner Side Milling, Side Milling Chamfering, Parabolic Milling, Profile Milling, Chamfer Side Milling, T Type Slot, Carving milling, Internal Chamfer